Articles

Thermopanels

UAB Vytrolma

Thermopanel element system: characteristics and advantages

Today with the quick advancement of technology, progress and innovative solutions do not avoid the construction sector. This gives an opportunity to offer the advanced solutions to our clients, which combine modernity, efficiency and economy. For those looking for quality, quick mounted and attractive facade design solutions, we offer the thermopanel element system.

When is it worth to choose the thermopanel system?

Thermopanels are an ideal option for commercial, public, and industrial buildings, as well as for the renovation of old construction buildings and their modernization. Thermopanels are also appropriate for the residential houses.

The quality thermopanel element system is fast installed and is suitable not only for the wall finishing of external buildings, but also for the roof constructions and overlays.

This system is easily adaptable, and it is its great advantage. It does not limit your decisions, and you can use any exterior finishing and architectural configuration.

Thermopanels: what is the composition of elements?

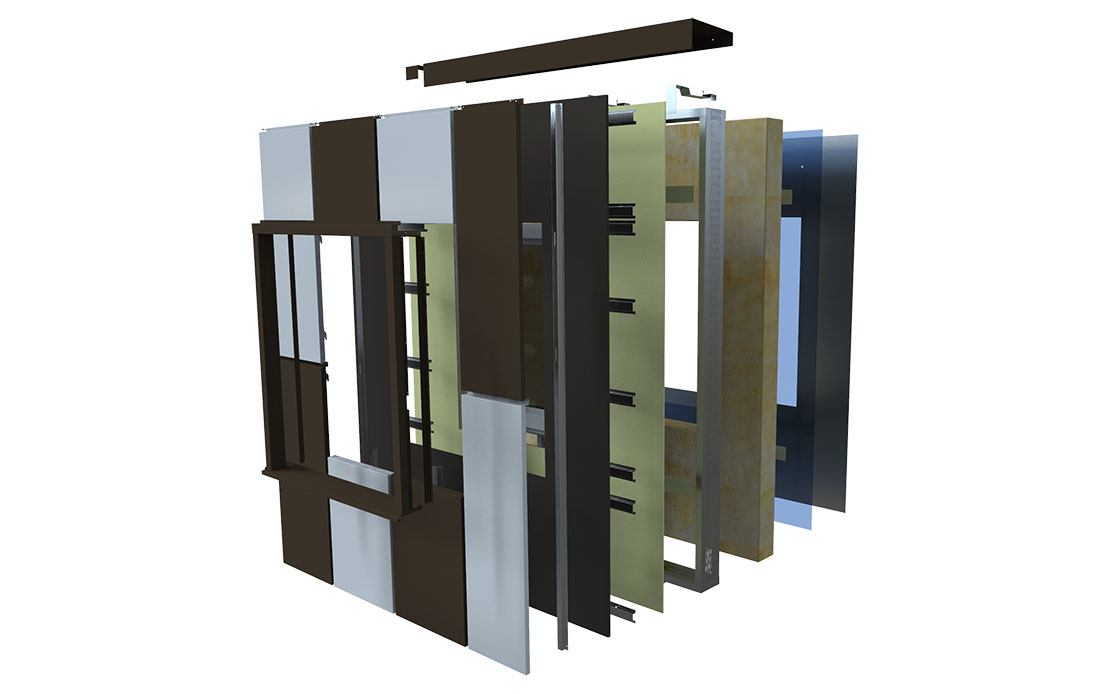

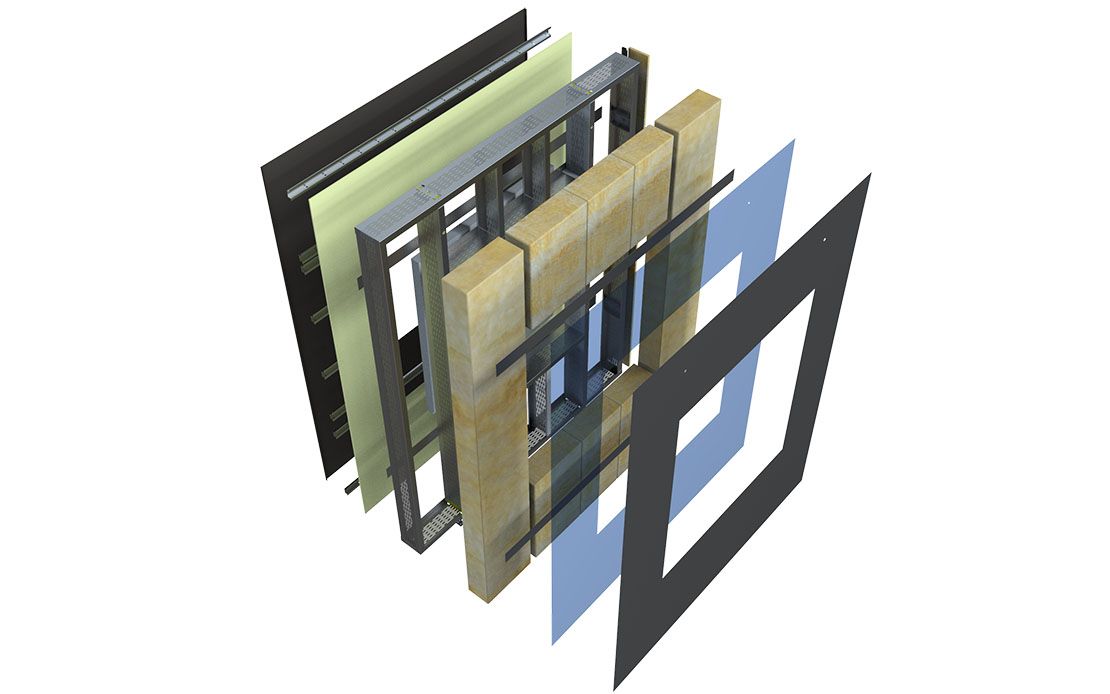

Thermopanels consists of six components:

The first layer is the finishing. As mentioned before, it can be chosen according to the needs and possibilities. Steel or other metals will suit those best who want longevity, durability and minimal time for maintenance. Those who prioritize ecology and nature can choose wood. Choose glass for the contemporary, aesthetic and modern design. A finishing layer of natural stone or decoration bricks will give a luxury look, and will be long-lasting. You can also choose visually good looking ceramic tiles or common for many plaster facades. Those who value an attractive design, economy and functionality, should prioritize a ventilated facade.

Another thermopanel component is the air gap (20 mm). It is made by using lathes and is necessary to protect the facade finish from the condensate accumulation and other negative factors, which would be unavoidable without the air gap.

Under the lathes is the wind-insulation board, such as 9 mm plasterboard, 12, 25 mm or other thickness porous wood fiber board, and a choice of 4 or 8 mm thickness cement chipboard. Plywood is also suitable for wind insulation, and could be 6.5 or 9 mm thick.

Another layer is thermal insulation and thermoprofile. Non-combustable materials with properties of excellent thermal conductivity are used, such as rockwool or mineral wool. Thermoprofiles are made of steel, thus, they are durable, high quality and impeccably functional. The choice of profiles is wide: T, TU, U, C, TC and other shapes. Thermoprofiles can be from 0.5 to 3 mm thick. The role of thermoprofile is crucial here, and it is very important to choose a quality product. Steel used for the manufacturing of thermoprofiles gives an opportunity to produce thin and light-weight constructions, which are also firm and resistant to climate factors.

Another layer of thermopanel element is steam insulation, which is assured by quality LDPE polyethylene which perfectly serves its function. Steam insulation in this element is as important as any other part. It secures the building construction from water vapor. Thus, only materials with minimal vapor permeability are used.

The last layer of the element is interior finishing panels. Their supply allows a range of possibilities. Usually clients prioritize hardened gypsum boards or wood gypsum boards. Those who value durability, resistance and longevity choose steel sheets.

Total frame thickness varies over a wide range and depends on the type and characteristics of the materials used. We can produce thermopanels from 2.5 to 6 meters long.

Our thermopanels have extraordinary properties of heat and sound insulation and are fire resistant. Why trust us? We offer the best complex solutions to our business clients. Buying from one party effectively saves both your time and finances. We provide design and consulting services and help to choose thermoprofiles of right parameters. With over 25 years of experience, continuous improvement of knowledge, interest in foreign countries’ good practices and high competency of our human resources provide us with an opportunity to offer the highest quality services. Our solid list of major implemented projects illustrates our competency, client confidence and success in the sector.

What are the types of thermopanel elements?

We have four types of thermopanel elements in our assortment: rectangular, linear, industrial buildings and box type. What type of buildings is suited best by each type? We recommend rectangular or linear element systems for the commercial, office buildings. Rectangular element system will be a good choice for the multi-storey residential buildings as well. The industrial element systems will suit best the industrial buildings. The box or rectangular element systems would suit residential buildings.

Maintenance of thermopanels

Thermopanels will be a great choice for extra-large buildings, as they do not require any maintenance. The wall construction does not require maintenance as well, as it is secured by the thermopanel system. In order to achieve high efficiency and functionality of thermopanel elements, the installation is very important. You should entrust this only to the professionals with the right knowledge and skills.

Thermopanels are an innovative, functional solution with great technical characteristics. It is ideal for various buildings, especially large ones.