Articles

Metal Bending

UAB Vytrolma

Metal Bending: Why Trust Professionals?

Metal bends are highly sought after in the construction sector. Metal longevity, durability and solidity are highly valued features. Metal bends not only look solid, modern, but they are also functional.

Metal bends: production and peculiarities of folding

The resilience and plasticity of the metal are two features that form the basis for its machining capabilities, such as bending. Metal folding manufacturing of UAB "Vytrolma" is based on qualified and solid experience in the human resources team and advanced, modern equipment, which allows them to get the best result. For the final product, the metal is cut, bent, if necessary perforated, and laser cut. We use advanced, modern fiber-optic laser cutting machines, which enable cutting of steel, stainless steel, copper, aluminum with a thickness of up to 10 mm.

Available CNC (Coordinate) Cutters can be used for simple cutting, as well as for forming (up or down), marking, threading and other functions.

The spectrum of metal bends use is wide, and the folding process requires appropriate equipment and abilities. We use aluminum AW1050, AW5005, AW5754 for strength, durability and machining. We also work with stainless steel and galvanized steel DX51, S250GD + Z275, S350GD + Z275. We choose only high-quality, solid, durable and reliable materials to achieve the highest results in the long term.

Our experience in this sector has been longer than two decades. The purified working methods, technologies, acquired and constantly improved knowledge, and skills are a great advantage, allowing us to offer our customers a variety of solutions. We help to implement even the large projects and find solutions for the most demanding clients.

Equipment used in the manufacturing of metal bends

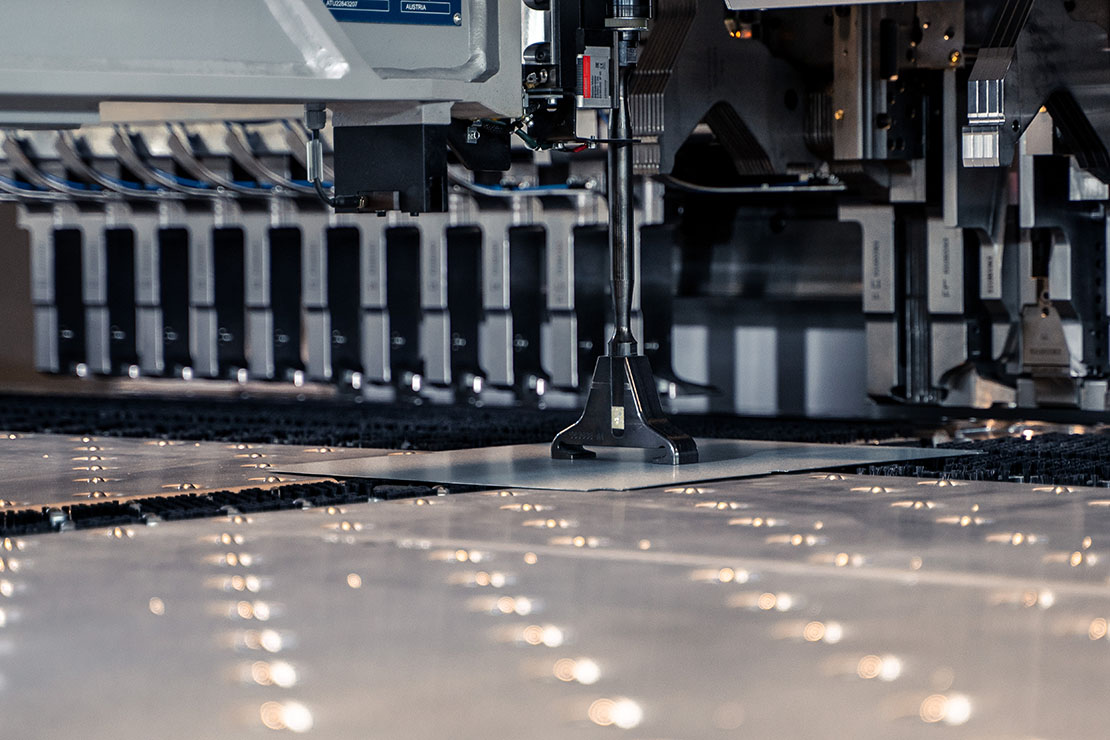

We pay a lot of attention to the equipment we use for the production of metal bends, and we prioritize modern, advanced solutions that allow us to efficiently optimize metal folding processes.

Metal cutting machines cut metal sheets very precisely. We have several cutting machines, thus we can cut metal sheets up to 0.5 mm thick and up to 4 meters long.

Metal bends are made using metal folding machines, which differ in such parameters as tonnage, possible width, number of axles and many more. Metal folding machines with different technical characteristics allow us to provide our customers a wide range of services. We offer the solutions that perfectly meet our clients’ needs. The company has a modern folding robot in its arsenal of machine tools. The wide assortment of folding devices implies that we can offer our customers up to 8 meters long and different thickness (1-6 mm) metal bending services.

We offer special ironing. We can smooth steel even up to 5 mm! This is a great solution if the metal has lost its flatness for one reason or another.

We can quickly perforate large quantities of metal products with the high-speed press punch. The maximum work piece dimensions are 2,000 mm wide and 4,000 mm in length. Metal sheets can be perforated up to 4 mm thick.

With the press machine we can insert the necessary nuts or bolts into the work pieces; this allows us to offer our clients a variety of solutions.

Laser cutting equipment enables accurate precision cutting. Laser cutting equipment can cut steel up to 10 mm thick. Maximum possible dimensions of the work piece to be cut by laser are 2,000 mm wide and 4,000 mm in length.

Metal profiles: shape and properties

Metal profiles, which are one of the most popular metal products, are in high demand in the construction sector and are indispensable for the construction of logistics complexes, warehouses, large hangars, industrial and commercial applications, administrative and other buildings.

We offer production of metal profiles services. The wide choice of profiles, such as L, U, T, TU, Z, C, TC, and Omega, allows every customer to discover the best product for themselves. We produce metal profiles from steel, as well as aluminum. Our metal profiles have the following features:

- lightweight but solid and durable;

- strong;

- easily transported;

- resistant to corrosion, which is particularly relevant for external walls.;

- quickly installed, which will speed up the construction process and save time.

Metal profiles can be from 0.5 to 3 mm thick and up to 8 meters long.