Articles

Painting of Aluminum

UAB Vytrolma

Aluminum painting is not as simple a process as it may appear at first glance. The dyeing of this and other non-ferrous metals requires specific knowledge and excellent understanding of the respective paint and metal properties in order to achieve excellent paint adhesion to the metal. If you want the highest quality aluminum paint, trust us; the modern equipment at "Vytrolma" and the professionals working here will make sure that aluminum is painted perfectly.

Our factory have innovative, modern "Gema Switzerland GmbH" and "Euroimpianti SRL" automated dyeing machines that prepare the aluminum surface for painting, and then paint it automatically with powder paint.

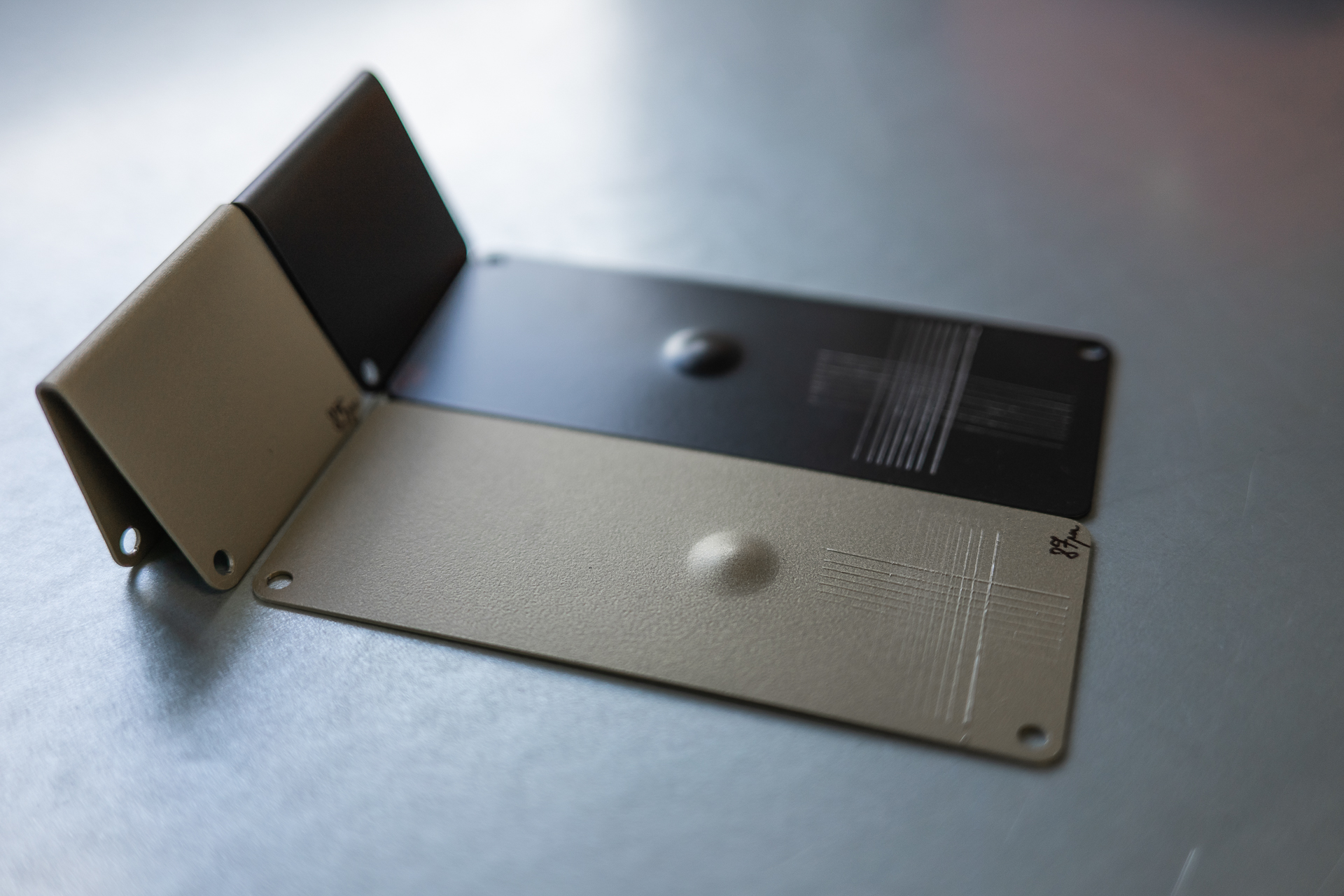

Our factory meets the high "Qualicoat" standards. We do not only prepare the aluminum before painting, and then paint it here, but we also perform various tests to the already painted surface. We evaluate the possible results, if necessary, improve them, and offer our clients only the final result of the highest standards. Thus, we test paint an aluminum plate with each order, and then carry out necessary tests such as impact, bending, indentation and others. We also measure the thickness of coating in different places in order to calculate the uniformity. These tests make the assessment of the possible outcome and identification of the need for improvement possible.

We also use „Seaside“ aluminum paint preparation, which includes two methods. The standard method is mandatory, and the reinforced method is optional. In order to achieve the highest level of oil removal, we apply both methods to the corrosion effect.

Characteristics of Aluminum Painting by Powder in "Vytrolma" Dye-House

The initial stage of aluminum painting is its preparation. For this, we use the environmentally friendly "Oxsilan AL 0510" technology, which does not contain any chromium compounds and is certified by "Qualicoat". The chemical preparation of aluminum for painting is necessary if we want not only to perfectly and qualitatively paint the metal, but also to preserve all the advantages of powder painting, such as fading color, reliable corrosion protection, and many others. Chemically treated aluminum must be dried at high temperature before painting.

The next stage is powder coating. We only use "Qualicoat" certified powdered polyester paints. The principle of powder coating is the spraying of negatively charged dry powder paint on a metal surface that is positively charged. The paint-coated metal is heated in a special furnace for about half an hour at high temperature, where the dry powder paint melts evenly over the aluminum surface. Powder coated aluminum features characteristics as durability and high resistance to moisture, sunlight and other external influences, as well as mechanical damage such as scratches.

Our technology line is suitable for products with a maximum length of 3.6 meters, height up to 1.6 meters, and width up to 0.6 meters.

The price of powder coating in our dye-house varies for each and every case and depends on criteria such as the color, surface of the metal and its quality, the area of the metal being painted, the desired effect, and many others. We focus on big projects, as we have a lot of experience working with big business entities. We paint aluminum fast, while maintaining quality as a top priority. We paint up to 1500 m2 of products per day.

What kinds of paints are used?

We use only reliable and high quality architectural paints with "Qualicoat" certification for aluminum coating. Paint does not contain any toxic substances, thus it is a great solution for the environmentalists.

We use "Qualicoat" 1 and "Qualicoat" 2 grade paints. The grade choice depends on where the painted facade will be built and which specific details will be painted.

A wide range of paint colors will allows you to choose the one that suits your needs best. Colors can be matte or shiny; they can vary from gloss 30 percent to gloss 85 percent.

We provide a 10-year warranty on peeling paint. We can also provide a paint supplier warranty. We select only responsible, cooperative and certified paint suppliers.

Why is Aluminum Painting in the "Vytrolma" Dye-House the Best Solution for you?

We have been in business for more than two decades, thus the experience and gained knowledge allows us to offer the best solutions in the aluminum painting industry for our clients. We are innovative and flexible, and we are always interested in the latest technologies, aiming to modernize our business processes and search for innovative ways to implement one or another solution.

We collaborate with other European countries and maintain close relations with the advanced Scandinavian countries. We are constantly looking for examples of good practice and adapt them to our business activities.

If you are choosing between powder coating and another painting option, do not hesitate and choose the powder coating. This method is much better. The metal painted this way has longevity and excellent corrosion, environmental effects and scratch resistance properties. This coating allows the product to be covered evenly, making it a high quality visually appealing product. Powder coated aluminum dries faster, and in many cases powder coating.